Michael Huber, CAD/PDM Administrator Paths are made by walking them

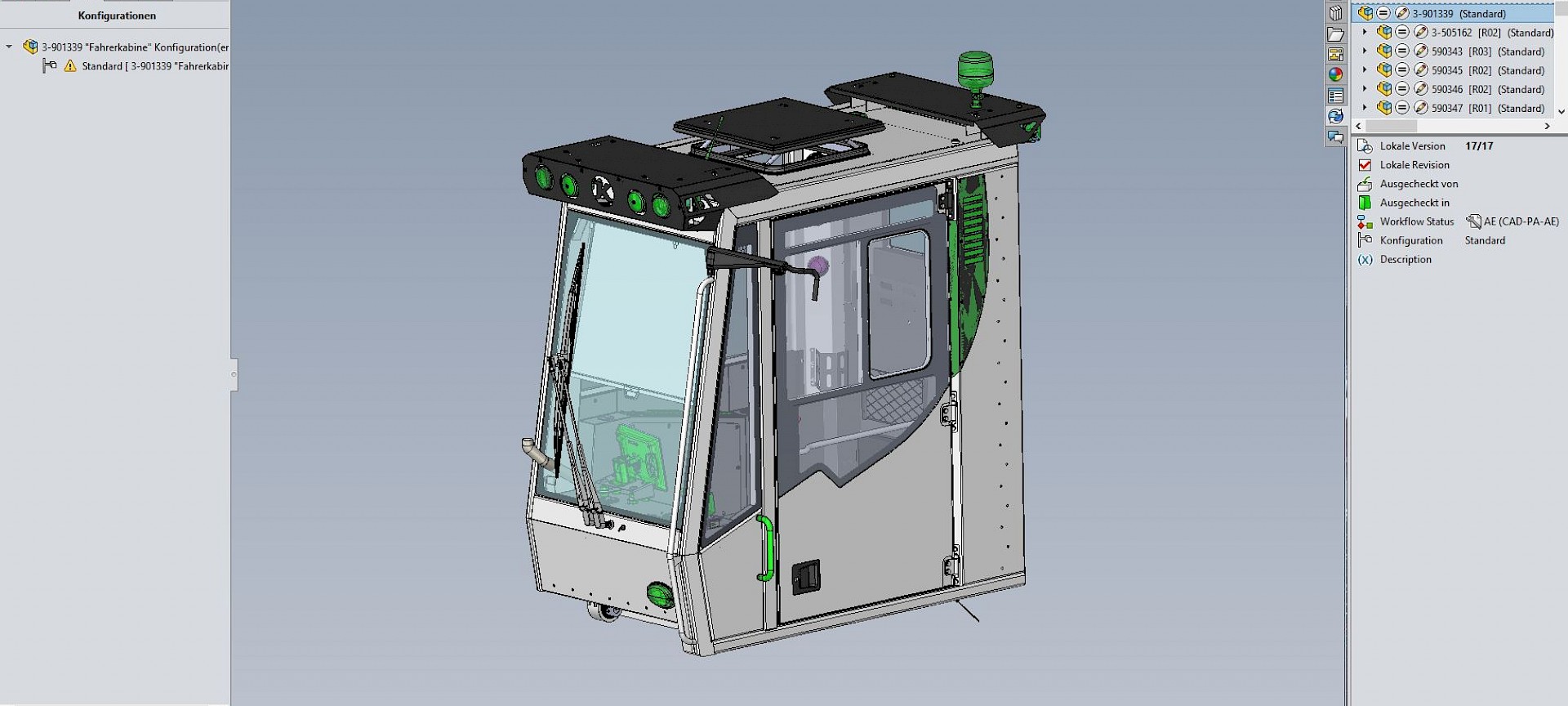

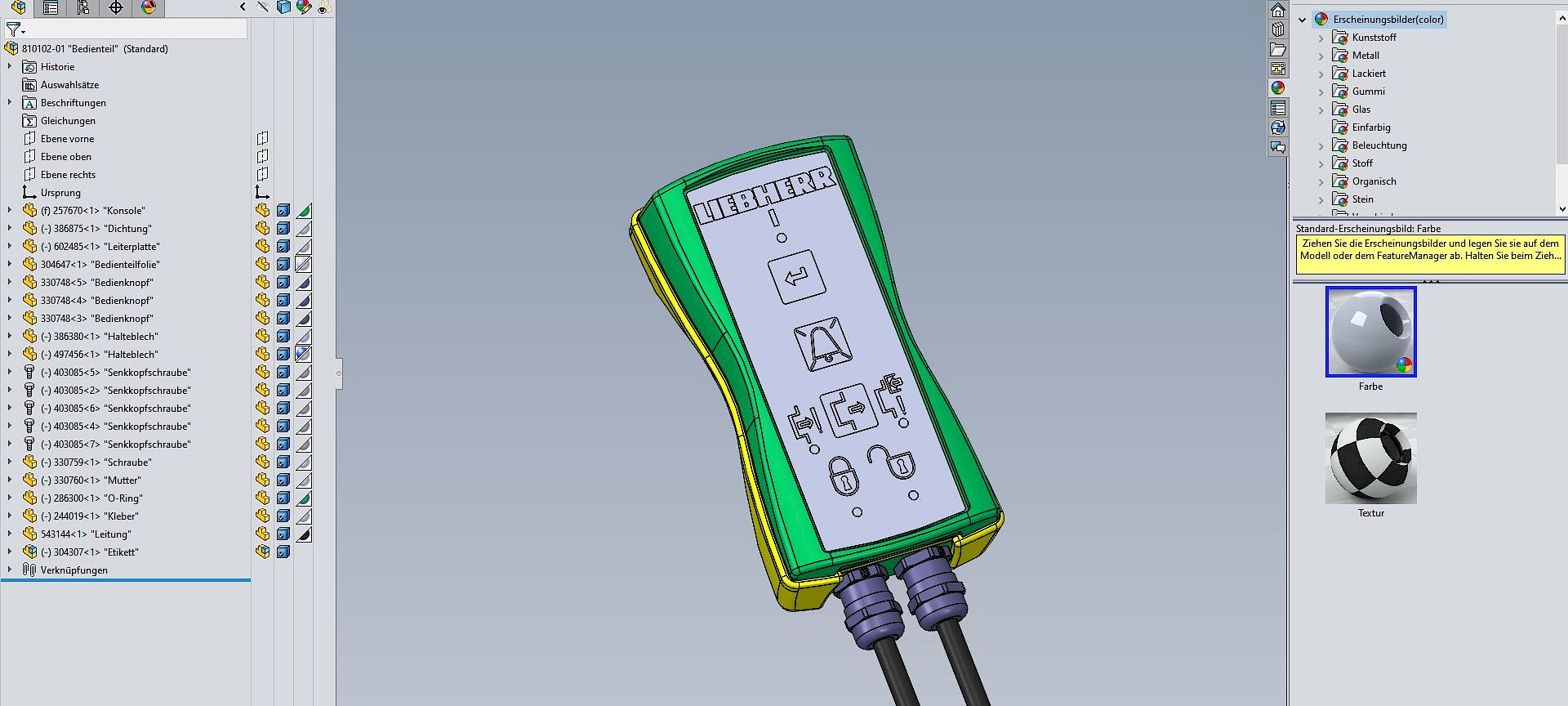

Michael has been working at Wölfle's Engineering office since 2008 as a designer and CAD/PDM Administrator. In his employee story we learn more about the 3D CAD system at Wölfle. The 3D CAD software SolidWorks in connection with the PDM system SolidWorks PDM Professional has become a very important tool for the designers of our company. In addition to the basic functions of a modern 3D construction solution, it offers our designers many added values that are advantageous in construction and development processes in order to be able to work faster and more efficiently. Let's take the example of a driver's cab that has long since developed into a high-tech workplace and has to meet the highest demands on ergonomics and design while taking costs into account. This can only be achieved with an efficient CAD tool and a pragmatic PDM solution. For this reason, our company decided to switch from another 3D CAD system to SOLIDWORKS 3D CAD and SOLIDWORKS PDM Professional.

-

Seit 2008

at Wölfle

-

Kreativ als

CAD administrator

-

TB

Teamwork

-

SolidWorks

Software

Creative freedom and complete documentation

We have also come to appreciate the ease of use and administration - today we use the complete range of services from SolidWorks PDM Professional not only for organising cooperation in the design team. We have mapped our entire construction processes with workflows and thus reflect our way of working in the system.

It is also very important for us that we can now access various previous development statuses relatively easily. This creates creative freedom and seamless documentation of the product development process, which is particularly important for long-running projects.

Furthermore, the PDM system saves us a lot of routine work and redundant inputs that we previously had to do manually. Using the workflow-based export function, we create and update our articles and parts lists in the ERP system synchronously with our design statuses and releases. At the same time, the task server generates 2D and 3D PDF data when the construction data is released. This data is then automatically available company-wide with the current status.