COMPETENCES ... WERDEN IN THEORIE UND PRAXIS ERWORBEN UND STEHEN ALS FÄHIGKEIT BEI HERAUSFORDERUNGEN ZUR VERFÜGUNG

Our strength lies in the development and implementation of product ideas and innovations in series products and system solutions. Clever solutions are the result of a profound understanding of technologies, feasibility and customer requirements. As a leading technology supplier, we have stood for efficient and inventive solutions and products for the driver's workplace of commercial vehicles and machines on and off the highway for over 50 years.

Product development process Development partner for tailor-made solutions – From idea to success

The task of our engineers is not just to develop solutions, but a dynamic process in which the experience from many projects is combined and in which our customers are intensively involved. Our success is based on sound technical and methodological expertise. Our product development according to the V model is a core process in our integral product development process (PEP). We can offer our customers the entire PEP or synchronize with our customers' processes. Depending on the application, the optimal process must be determined. Our process can be flexibly applied to simple component developments as well as complex system developments.

-

CONCEPT PHASE

Concept study or inquiry, preliminary development / solution finding, functional model / feasibility study

-

DESIGN PHASE

Product definition / specifications, design, software and hardware development, system development & integration, analyses, simulation & calculations

-

VALIDATION PHASE

Trial and test phase, verification, validation product / vehicle

-

PRODUCTION PREPARATION

Production concept, production planning, purchasing and parts qualification, pre-series phase

-

SERIES PRODUCTION

Start of Production (SOP), series support, change management, product cost and process optimization, support at EOL (End of Life)

Development WÖLFLE INSIDE – SUCCESS COMES WHEN EXPERIENCE AND CURIOSITY COME TOGETHER

Unser Ziel ist es, ein Produkt termin-, kostengerecht und qualitativ hochwertig auf den Markt zu bringen, dafür bietet uns der auf Wölfle maßgeschneiderte PEP (Produktentstehungsprozess) die Grundlage. Zunehmende Produktkomplexität verbunden mit steigendem Softwareumfang sind Herausforderungen, die viel Erfahrung und eine kreative Lösungskompetenz erfordern. Vernetzung von Entwicklungsteams, Anwendung agiler Methoden, Simulation und Rapid Prototyping sind angewandte Praktiken zur Beherrschung der Komplexität und zum Zeitgewinn in der Umsetzung.

- Safety and Security

- CFD Simulation

- FEM Simulation

- AUTOSAR®

- KULI Simulation

- FEM Simulation

- MATLAB®/Simulink®

-

Networked development

4 business areas

-

Test and validation center

Wölfle Inside

-

Technology professionals

Unique development expertise

-

Solution guarantee

Wölfle DNA

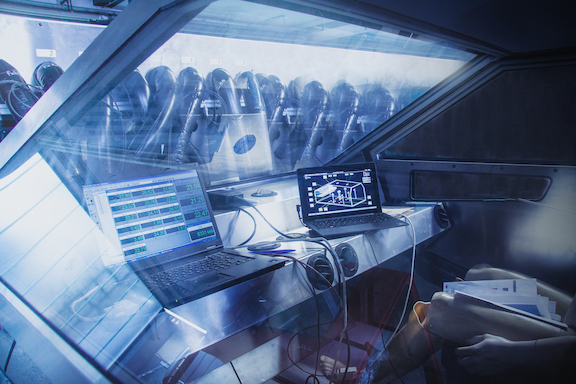

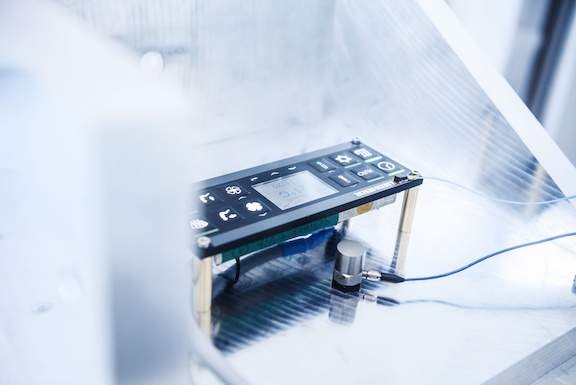

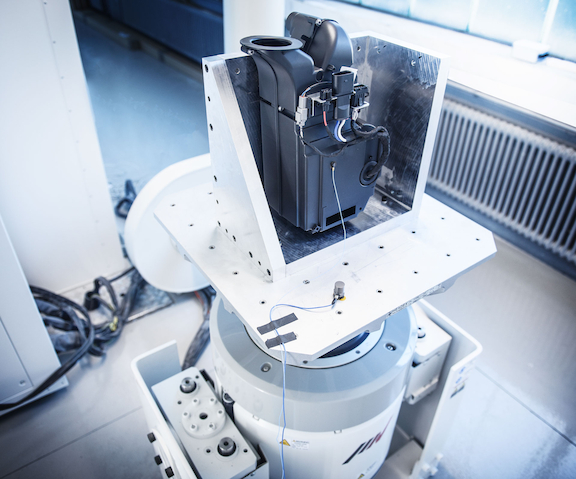

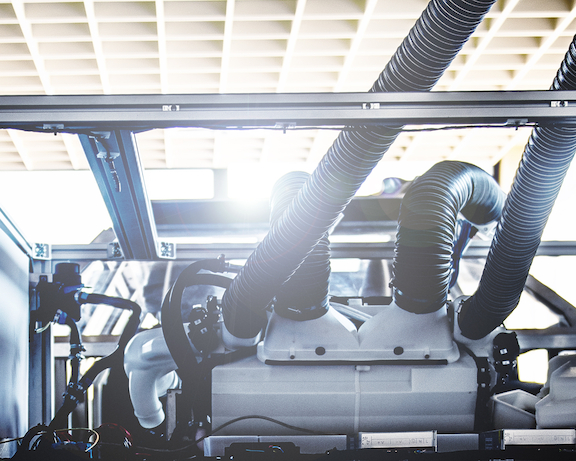

Wölfle Test Center State-of-the-art measuring and testing technology Wölfle Test Center

Important findings during the product development process are gained in the trial and test phase through testing, trials and qualification. In addition to proving their functionality, the products must also demonstrate their operational stability under stress conditions. The influences of extreme mechanical, electrical and climatic stresses are taken into account according to a coordinated test plan.

We are well equipped in our test center and can rely on a wide range of equipment when carrying out the necessary tests. If this is not sufficient, we can rely on numerous partners who actively support us, for example crash tests.

Mechanical tests

Vibration test sinus

Vibration test noise

Shock test

Tensile and compressive force test

Digital microscopy

Micrograph laboratory

Electrical tests

EMC equipment

Functional test

Insulation resistance

Electrical laboratory equipment such as power supplies up to 1000 VDC and 10 kW

Network and bus analyzer CAN and LIN

High voltage test

Environmental tests

Climate hall (link to page) and climate chambers – heat, cold, humidity, solar simulation

Salt spray test chamber

Resistance to various chemicals

Thermography

Environmental tests

Climate hall (link to page) and climate chambers – heat, cold, humidity, solar simulation

Salt spray test chamber

Resistance to various chemicals

Thermography

Other services

Development and endurance test benches

Design and construction of test devices

Helium leak test

3D measurement

Download data sheet

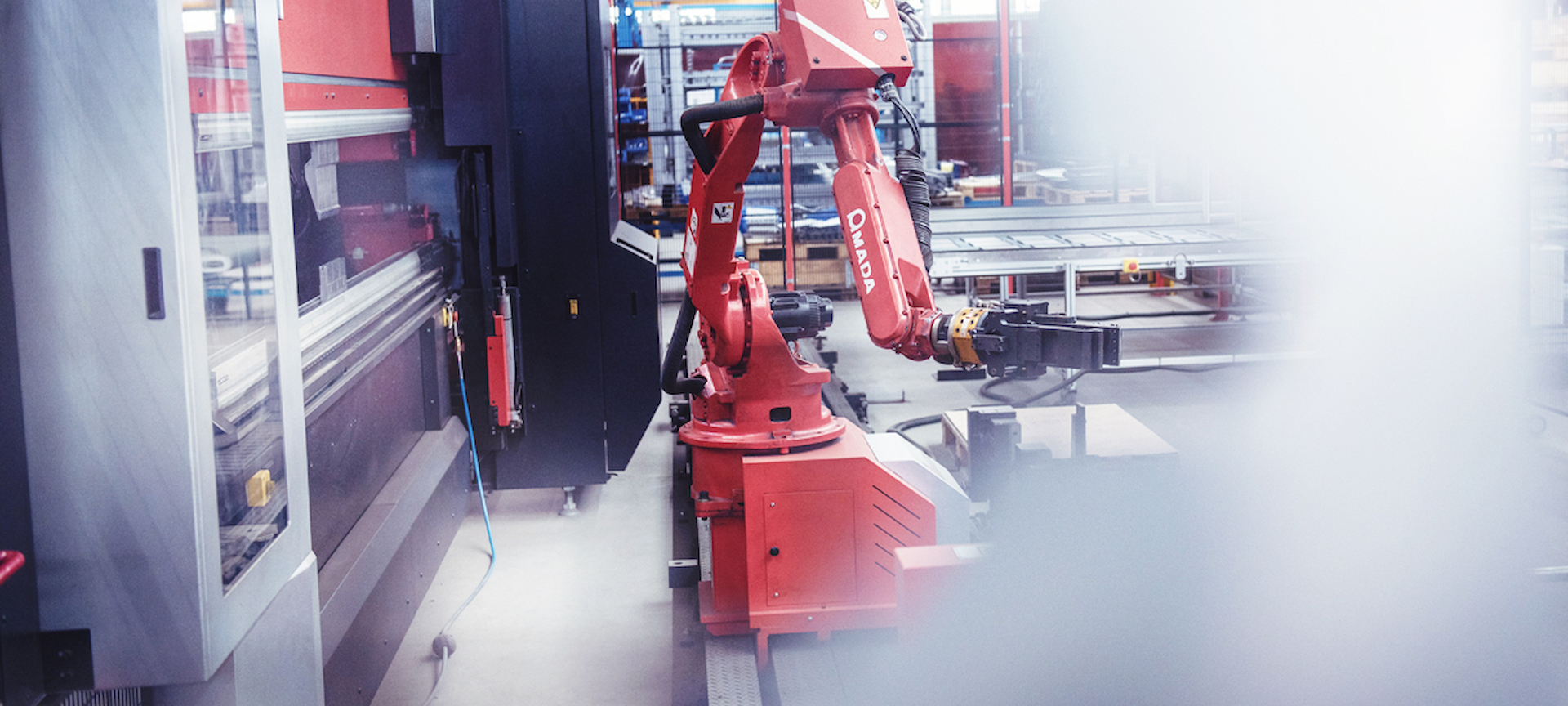

production WÖLFLE INSIDE – CUSTOMER ADVANTAGE

With its four business areas, Wölfle has comprehensive manufacturing expertise with a high level of vertical integration. Our main plant in Ochsenhausen is the control and competence center in our international manufacturing network. By networking and centrally controlling the plants, we achieve optimal operations and uniform processes across the group, which are implemented by local, operational production control. We gain flexibility and redundancy through consistent manufacturing options in our international manufacturing network, which is used to the benefit of our customers.

-

technology

Efficient & proven technologies for economical production

-

Production process

Reliable processes, efficient IT support and qualified employees, as well as methods for process monitoring and improvement

-

Resilience

Protecting the ability to act and be future-proof through flexibility in organisation and control, as well as redundancy in the international manufacturing network

-

customer focus

Fulfillment of customer and industry-related requirements. Our success is based on proximity to customers and high standards for ourselves

-

Plug & Play

Hoher Qualitätsstandard und optimierte Produktionskosten bei kundenspezifischen Produkten durch eigenen Prüfmittel- und Vorrichtungsbau für maßgeschneiderte Lösungen ohne Kompromisse

Quality WÖLFLE INSIDE – QUALITY IS NOT A PROMISE, BUT A BASIC ATTITUDE

Quality is the result of competence and creates trust. Quality is not just limited to whether a product or service meets the required expectations and guidelines.

Quality thinking is the responsibility of all employees and shapes all functional areas and processes of the Wölfle Group. It begins with the design, the product development process, the quality of the production processes and the skills of the employees - but all of our company's services contribute to quality.

-

QUALITÄTSMANAGEMENT

Our certified quality management ensures that quality can be planned and repeated. The optimal interaction of networked business processes must be guaranteed. Key figures provide important information for monitoring, controlling and improving.

-

SUPPLIERMANAGEMENT

Bei der Herstellung von Produkten ist man auf die Zusammenarbeit mit zuverlässigen Lieferanten angewiesen. Die Auswahl und Überwachung unserer Lieferanten nach festgelegten Kriterien und Qualitätssicherungsvereinbarungen sorgen für Sicherheit und Verlässlichkeit.

-

FEEDBACK &IMPROVEMENT

We pursue the idea of continuous improvement and root cause analysis. Quality control is ensured with our systematic and effective change management.

-

LOGISTICS /IT

Quality can only be achieved with secure transport, storage, provision and distribution of goods. In addition to the material flow as a core process in logistics, the secure flow of information is of central importance and forms the basis of all company processes.

-

SERVICE QUALITY

With our approach “From the idea to the ET (spare part)”, we offer competent support for our entire product portfolio through our aftermarket division, as well as comprehensive services over the entire product life cycle.