High-voltage electrification Distribute power safely

The electrification of vehicles presents many manufacturers with new challenges. High demands are placed on reliability and ease of use, particularly when connecting, distributing, switching, and securing high-voltage applications. Due to the current strengths, these devices are subject to high thermal loads, but must also be weather- and aging-resistant. Wölfle has been working on the topic of e-mobility for years and is working with many OEMs as a research and systems partner on the vehicles of tomorrow.

-

100%

customer-specific

-

Wölfle testing procedure

progressive and programmatic

-

Safe and robust

Technology of tomorrow

-

Just-in-Sequenze

Custom-made products

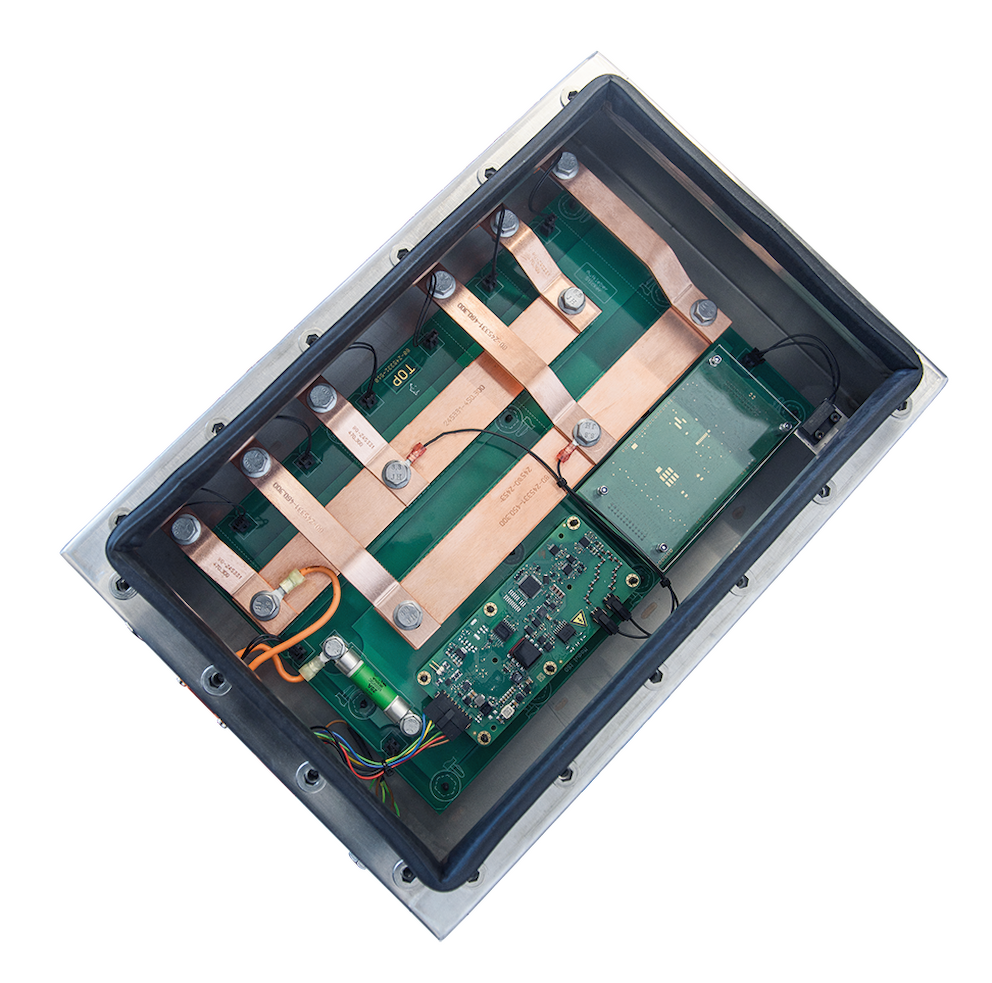

HV-PDU

- Diverse housing options

(Die-cast aluminum, stainless steel, and even customized solutions)

- Flexible connection solutions

(Plug-and-play for quick commissioning or wired configuration)

Active or passive cooling

(We guarantee maximum operational reliability and efficiency – even under demanding conditions)

Highest sealing – up to IP6K9K

(Maximum protection against dust, water, and high-pressure cleaning)

Modular, customized design

(Our systems can be individually adapted to customer requirements)

Validation according to current norms and standards

(We ensure that our products meet the highest quality and safety requirements)

Shock and vibration tests

(For maximum operational reliability even under extreme mechanical loads)

Comprehensive electrical tests

(Dielectric strength tests, insulation tests, pinning tests, EMC tests)

Applications:

Electric vehicle (BEV, FCEV)

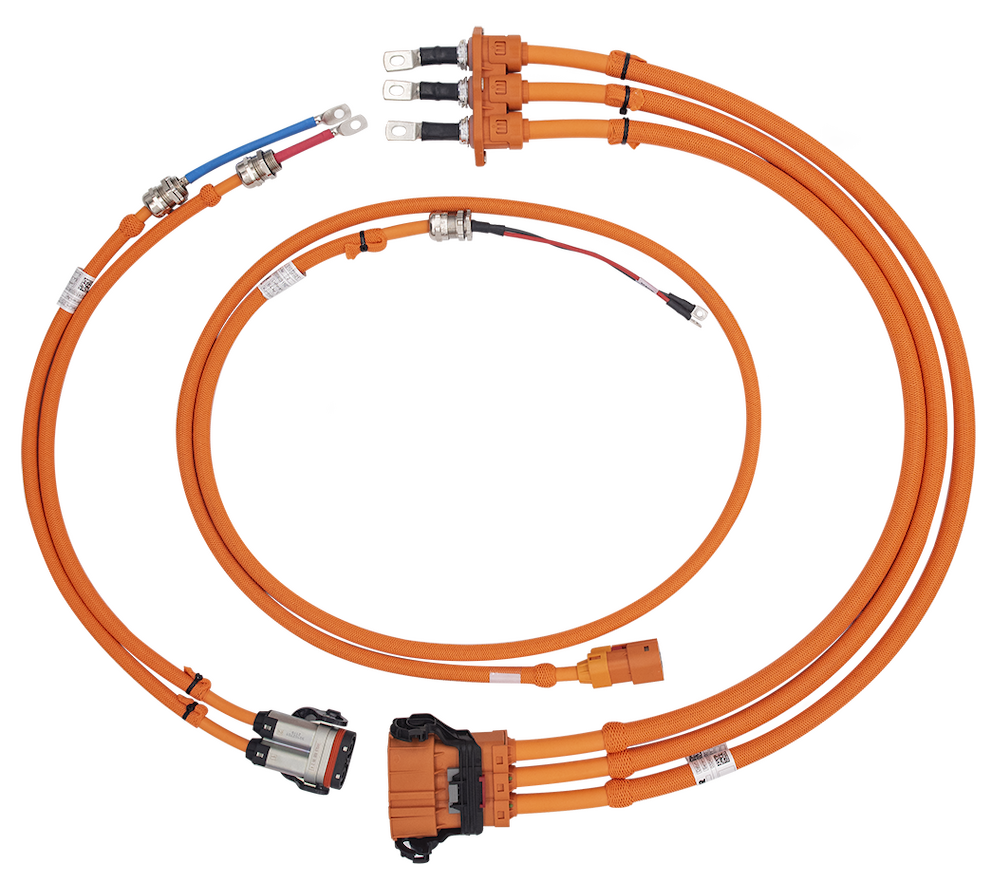

High-voltage cable

High-voltage-specific insulation

Maximum current-carrying capacity

High temperature resistance (-40°C to 180°C)

- Mechanically robust and abrasion-resistant

- EMI/EMC protection through special shielding

- Precise crimping technology for maximum conductivity

- Weather- and aging-resistant

- Fully automated processing for the highest quality

- Custom connector configurations

- Short circuit and overvoltage protection

High-Voltage Expertise – HV PDUs & High-Voltage Cable Harnesses for Tomorrow's Mobility

Building on our many years of experience in the development and production of low-voltage cable harnesses, Wölfle has consistently expanded its portfolio in recent years: Today, we create customized high-voltage cable harnesses and complex HV PDU solutions for a wide range of applications in modern vehicles.

Our development and production expertise is complemented by our own high-performance test center. This allows us to ensure that all regulatory requirements are met right from the development phase – precisely, efficiently, and future-proof.

Wölfle test procedures during development:

- Thermal tests

- Shock and vibration tests

- Leak tests

- Salt spray tests