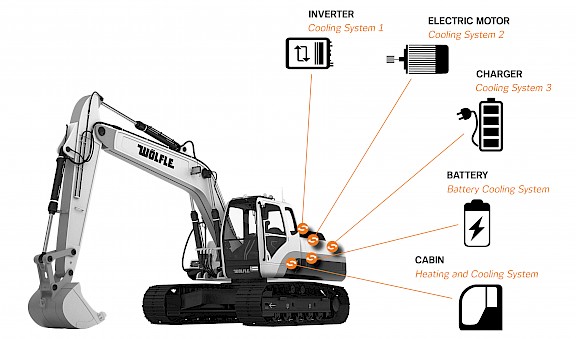

Climate control and automatic climate control The air conditioning of driver cabs is one of the most complex tasks in vehicle development.

Due to the individual operating conditions of vehicles and stationary applications, in addition to a reliable heating and cooling circuit, optimal climate control is also required.

Due to constantly changing temperatures, solar radiation and ultimately also individual needs, a heating or air conditioning system must react quickly and flexibly, but must also guarantee constant comfort.

Based on extensive experience in the field of control and regulation technology in conjunction with the specialist knowledge of heating and cooling circuits, Wölfle offers a unique expertise - from simple blow-out rules to PID controllers to mathematical energy models for fully automated climate control.

In addition to in-house hardware and software development, and in-house test centre with vehicle climate chamber, we also offer a comprehensive product portfolio. This includes, among other things, operating elements, heating and air conditioning controls and power controls, but also highly intelligent controls for a comprehensive thermal management of the vehicles.

-

Virtual sensor

Wölfle Energy Model

-

12 years

Experience

-

<1K

Control or temperature deviation

-

>70.000

in the field

Climate model Influencing factors

Comfort is becoming more and more important in our day and age - including for the everyday workplace.

Different temperature conditions such as heat in summer or cold in winter play a major role. Concentrated and ultimately successful work is only possible with a perfectly air-conditioned workplace.

Classic climate controls often reach their limits here, as these systems are mostly based exclusively on the values of the implemented sensors (internal temperature, external temperature, sun sensor, door contact switch).

Our Wölfle climate model not only includes control based on sensor values, but also takes into account the mathematical values of an energy model (so-called virtual sensor). Despite changing influences such as solar radiation, temperature jumps and open doors, this enables a predictive reaction of the systems and thus a stable temperature <1K.

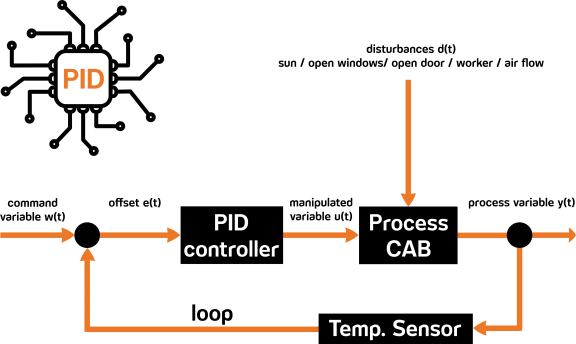

Climate model control systems Control method 1: PID / PI controller

A PID Controller (Proportional-Integral-Differential Controller) is a control loop that uses feedback data from the various sensors on the vehicle. The PID controller continuously calculates an error value as the difference between the desired setpoint of the temperature controller (e.g. 21° C) and a measured process variable (e.g. temperature sensors) and applies a correction.

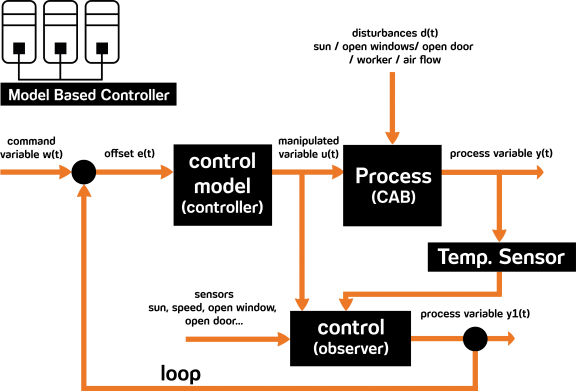

Model-based climate model Control method 1: Model-based controller

To put it simply, Wölfle climate model is the calculation of the indoor temperature using a complex energy model. For this purpose, a Matlab® model is generated from the HV/AC system and the (driver) cab. This model is able to calculate the indoor temperature at any time and in advance.

There are also lots of sub-controllers and models to improve the quality, wear and tear and the perception of the system. The Wölfle model is now being developed in the third generation and has since been expanded with numerous functions that, on the one hand, accelerate integration and adaptation to the vehicle (adaptation to a vehicle in a few days) and, on the other hand, allow for permanent improvement of the climate model in operation.

Model-based climate model (measurement recording) Control method 1: Model-based controller

The graphic shows a measurement of a counterbalanced lift truck. The temperature is shown on the Y-axis. The time in minutes on the X-axis. The blue line shows the outside temperature of the vehicle directly at the fresh air intake.

- You can see immediately at the start of the measurement that the fresh air drops to 3° C. The vehicle is in an environment of 0° C.

- After approx. 14 minutes the vehicle suddenly changes the ambient temperature (vehicle drives into a heated hall), approx. 26° C. It can be seen that the fresh air temperature follows an E-function.

- The temperature changes again after a further 24 minutes.

- The magenta-coloured line demonstrates the internal temperature of the cab (according to ISO mean). This shows that the internal temperature rises to 25° C and remains constant throughout the entire measurement.

Such a temperature profile can only be achieved using an energy model.

Markus Reich

Key-Account-Manager

Cabs Distribution

T +49 (0) 7352 / 929 130