Cable assembly Diverse, individual and produced with the most modern manufacturing processes

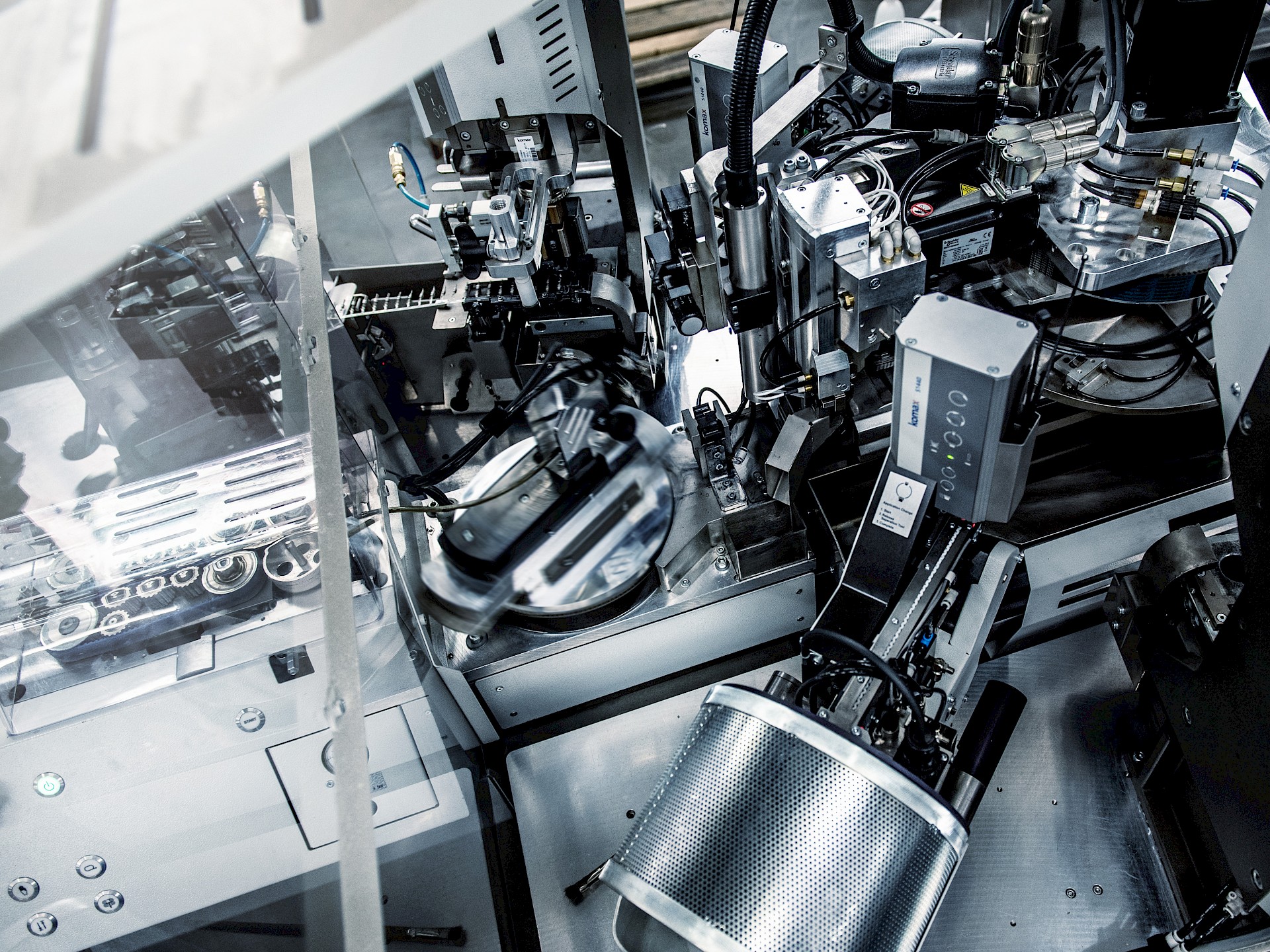

From individual battery cables to highly complex vehicle cable sets - in the area of cable assembly, we use various production processes such as table and cable board production, ultrasonic splicing technology, connector and wire printing, fully automatic crimping machines with electronic crimp force monitoring. In this way, motor cable sets, vehicle electrical systems, cable harnesses and various special cables are created. Everything in the best quality.

In the vehicles, the cable systems for the control of the vehicle components as well as the passenger comfort are becoming more and more important. This requires optimal connection and connectivity.

Vehicle cables from Wölfle:

At Wölfle, we produce resilient electrical systems of low to very high complexity and use the most modern processes and manufacturing technologies for this. With us you will find everything you need for the function and control of your vehicle and its individual modules and components.

For an individual product solution, our project team from Development and Construction is at your disposal from planning to series production of cable assemblies for your driver cab.

-

Particularly resistant

against biological substances and chemicals

-

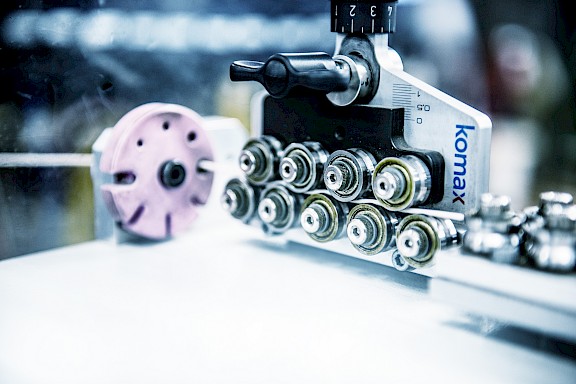

KOMAX®

best processing technology

-

200.000 Cable sets

Annually

-

100%

Heat and vibration resistant

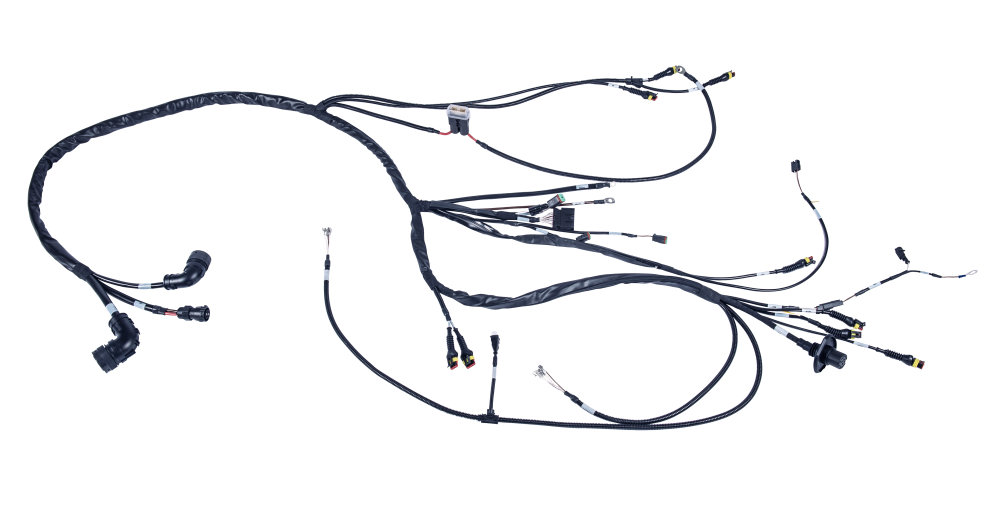

Vehicle harness

- Various sheaths such as yarn, corrugated pipe, protective tubes

- Cable set for the complete vehicle

- Highest manufacturing quality

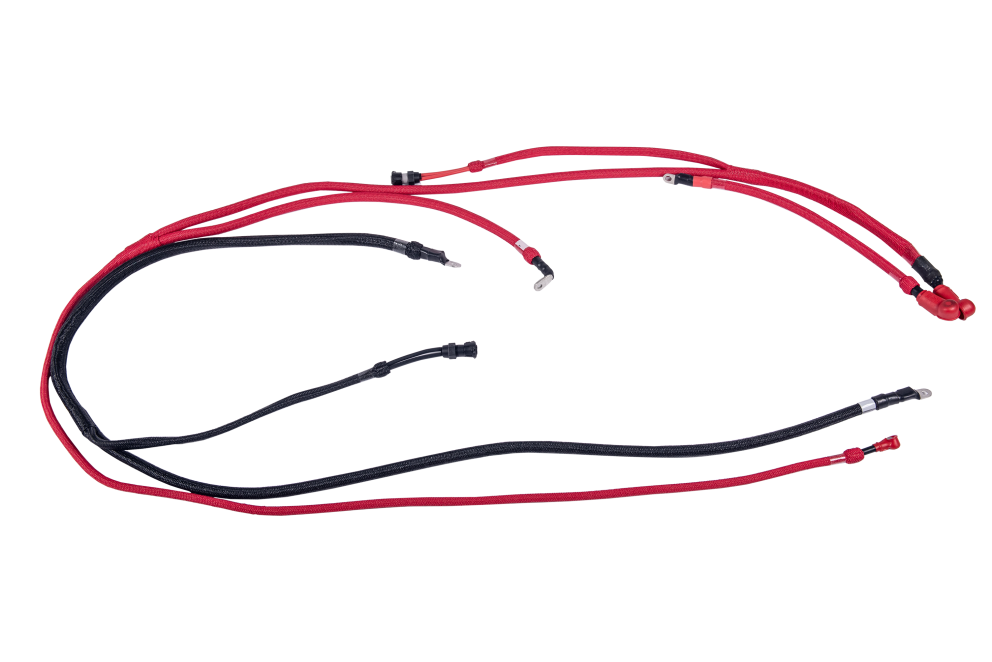

Battery cable

- Cable cross-section up to 120 mm²

- Crimp and soldering technology

- Various sheaths

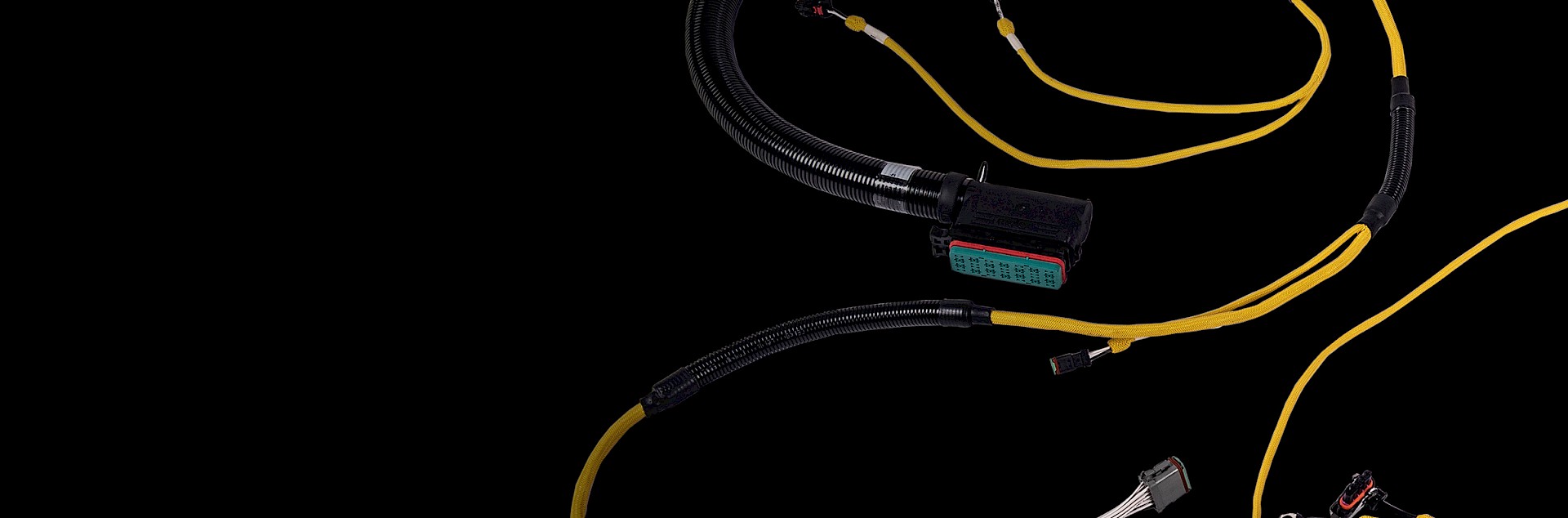

System cable set

- High resistance to biological substances and chemicals

- Sheathing with corrugated pipe

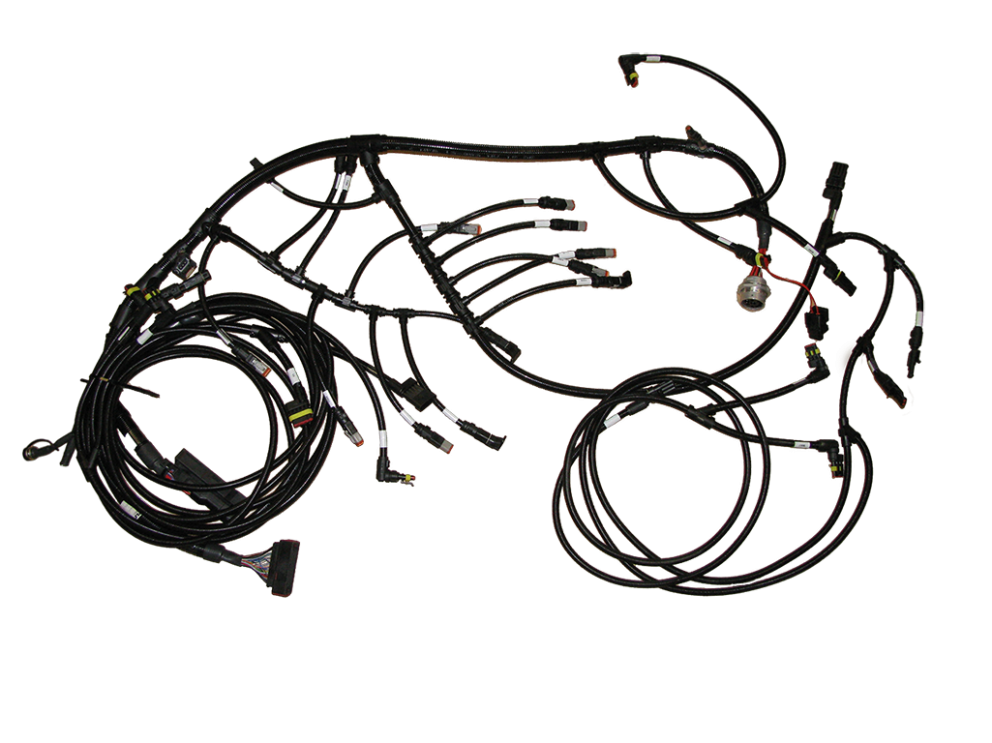

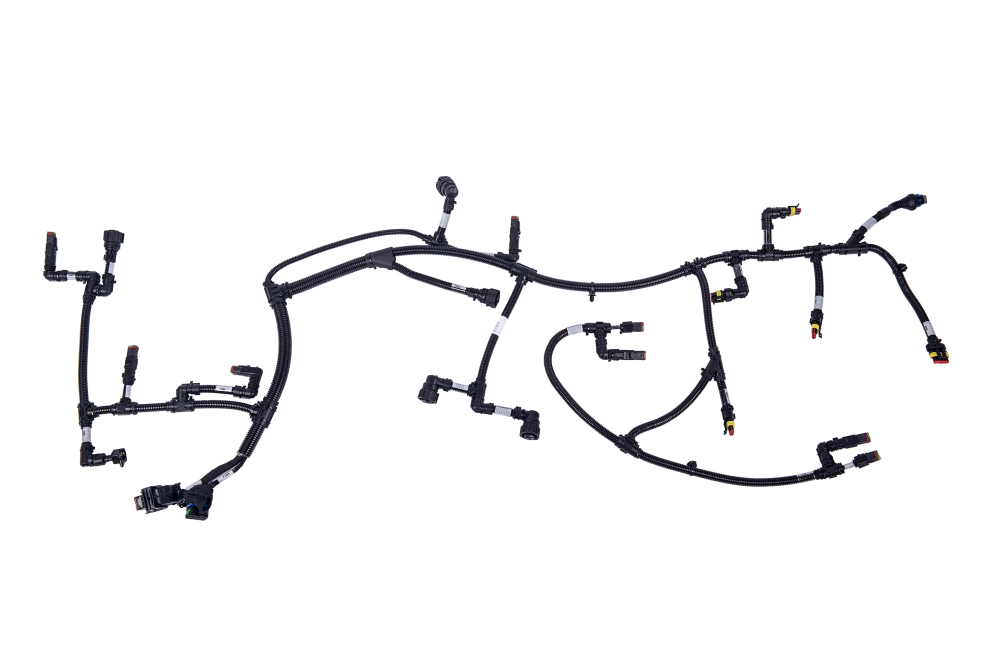

Motor harness

- 100% fully automatically struck by Komax®

- Cable and connector printing

- Extremely heat and vibration resistant

- Yarn sheathing - braided sheathing

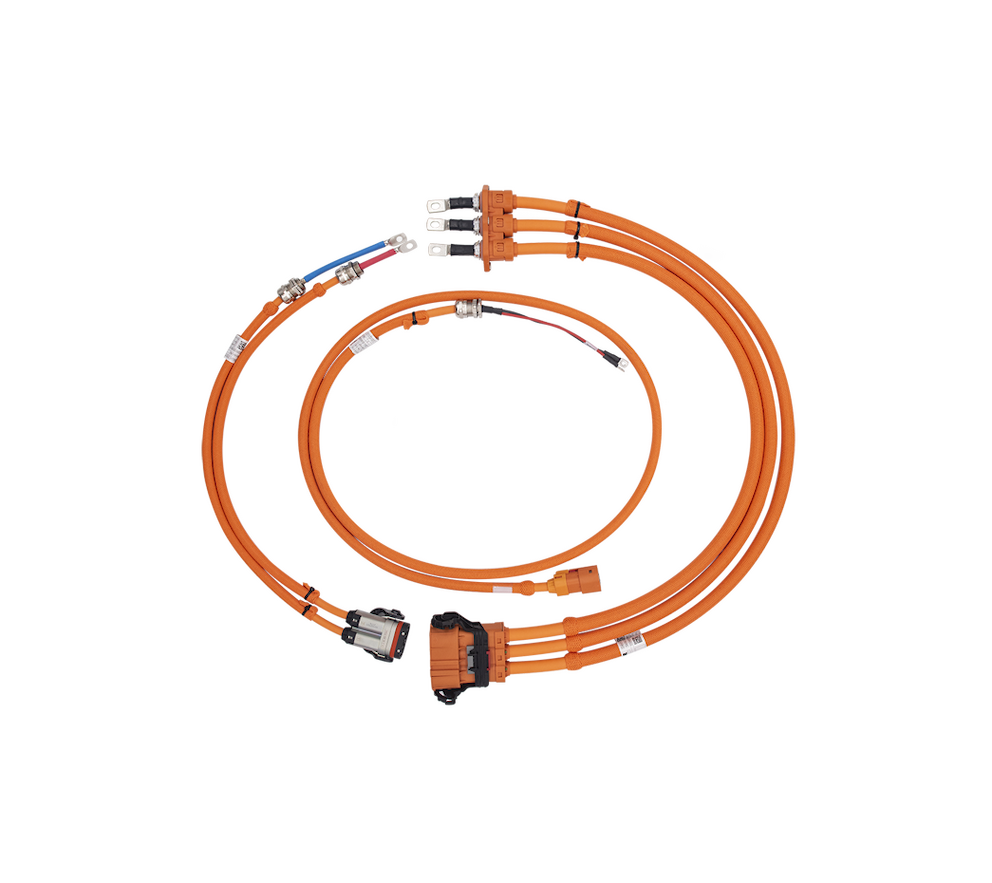

Battery cable

- Battery cable sets with multiple branches

- Connections of up to 215 mm²

- Various sheaths (corrugated pipe/yarn)

- Very good mechanical protection

- Large and small series

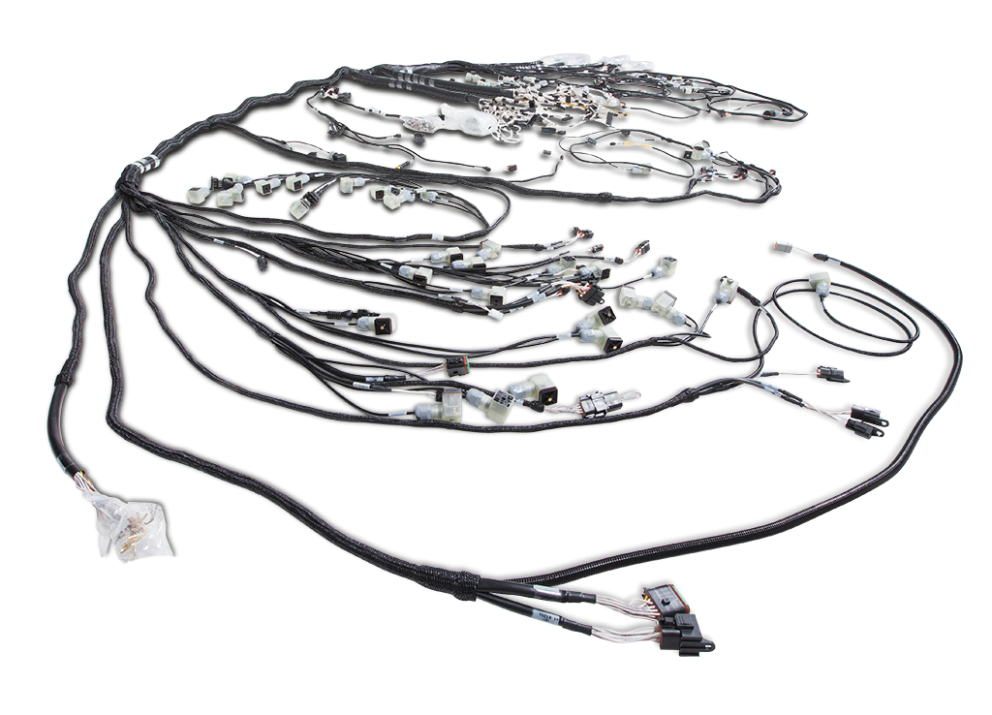

Vehicle harness

- Different sheaths

- Flexibility at branches

- Extremely durable and vibration-proof

- Moulded connector

- 100% machine chipped

- Printed forwards and backwards

Cable set

- Complete cable sets

- Various cables, plugs and sheaths

- Large and small series

- Table manufacture or laying board

High-voltage cable set

- Various sheaths such as yarn, corrugated pipe, protective tubes

- Cable set for the complete vehicle

- Highest manufacturing quality

- Vibration resistant

- Temperature resistant

Cable assembly We plan and manufacture your models

Our scope of development and services includes:

- Development and construction (with installation optimisation)

- Creation of documentation (circuit diagram, material list, CAD drafting)

- Prototype, sample construction and series production

Components / lines:

- Vehicle cables

- System cables

- Special cables

- Data cables

- Battery cables

Plug conductor:

- Standard and sealed

Protection systems:

- Fabric tape

- Insulating tube

- Corrugated pipe

- Shrinking tube

- Yarn braid

- Braided sleevings

Manufacturing processes:

- Table and cable board production

- Fully automated machines

- Automatic twister

- Ultrasonic splicing technique

- Connector and cable printing

- Knitting machine

Sara Kaiser

Key-Account-Manager

Electrics Distribution

T +49 (0) 7352 / 929 136

Andreas Stroh

Key-Account-Manager Elektrik

Vertrieb

T +49 (0) 151 / 73 026 026